+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

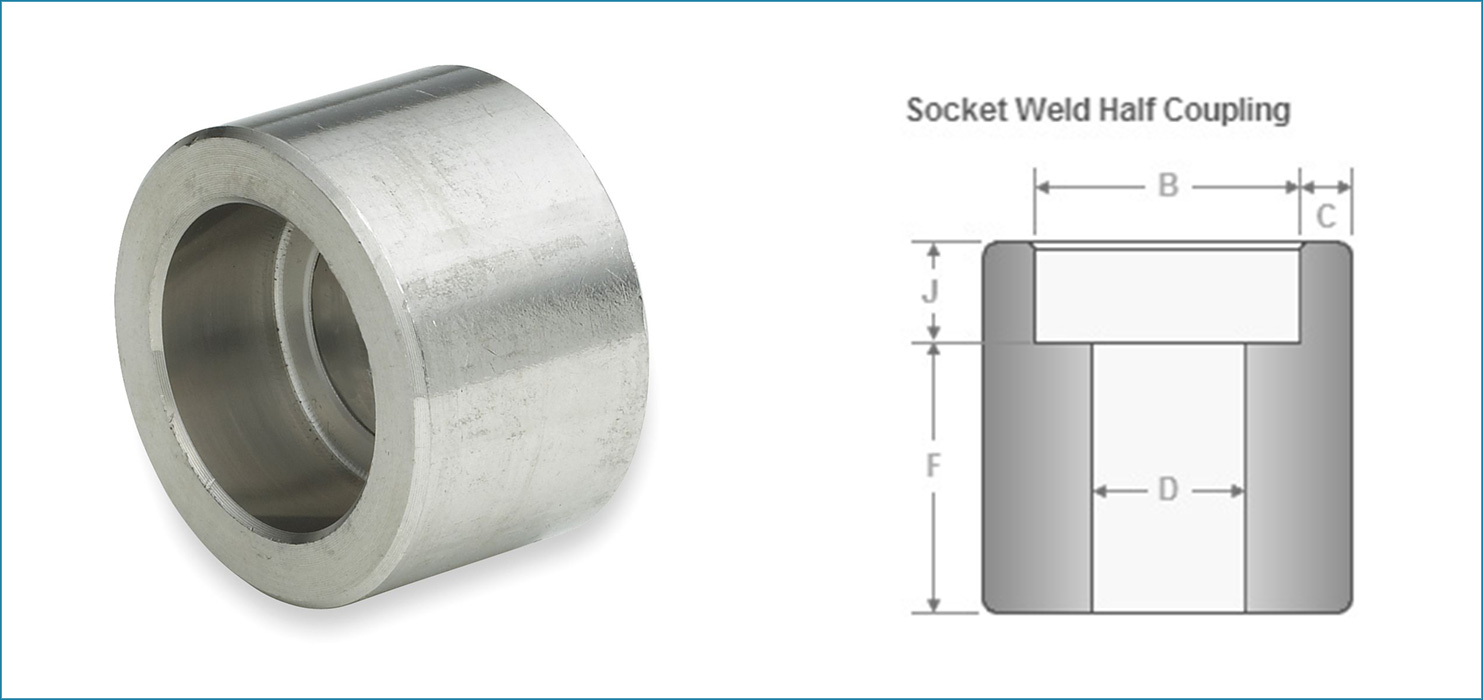

ASME B16.11 Forged Socket Weld Half Coupling

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B,

API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

1/8″ NB TO 4″ NB

HGFF Group Co.,Ltd is renowned manufacturer, supplier and exporter of Socket Weld Coupling with high-quality raw materials along with effective prices and fast delivery of goods are provided to the customer. ASME B16.11 Forged Socket Weld Half Couplings are well equipped with advanced technology which can be welded directly onto the run pipe to make a branch connection. Our offered ANSI B16.11 Socket Weld Coupling is used for various industries to connect pipes of different diameters.

HGFF Group Co.,Ltd is renowned manufacturer, supplier and exporter of Socket Weld Coupling with high-quality raw materials along with effective prices and fast delivery of goods are provided to the customer. ASME B16.11 Forged Socket Weld Half Couplings are well equipped with advanced technology which can be welded directly onto the run pipe to make a branch connection. Our offered ANSI B16.11 Socket Weld Coupling is used for various industries to connect pipes of different diameters.

Socket Weld Half Couplings is utilized in various applications in order to provide a torque-free sealing and a leak-free connection. ANSI B16.11 Forged Socket Weld Half Couplings supply in various sizes in order to fulfill their specific requirements which used in various industrial applications such as power generations, petrochemicals, etc. Buy these 2 Socket Weld Half Coupling at best price in China.

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB TO 4″ NB |

| Pressure Ratings | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Form | Couplings, Half Couplings, Reducing Couplings, Pipe Coupling |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Nickel Alloy Forged Socket Weld Half Coupling :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Stainless Steel Forged Socket Weld Half Coupling:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Socket Weld Half Coupling :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Socket Weld Half Coupling:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Half Coupling :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Socket Weld Half Coupling: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

| Forged Socket weld Half Coupling | Socket Weld Coupling Class 3000 |

| Socket Weld Pipe Coupling | 2 Socket weld Coupling |

| ASME B16.11 Socket Weld Pipe Coupling | 3000LB Socket Weld Half Coupling |

| 3 4 Socket Weld Coupling | Class 6000 Socket Weld Coupling |

| ANSI B16.11 Forged Socket Weld Coupling | BS 3799 Forged Socket Weld Coupling |

| Socket Weld Forged Coupling | Socket Weld Coupling Weight |

| Socket Weld Tube Coupling | Socket Weld Coupling Reducers |

| 2 Socket Weld Half Coupling | High Quality Socket weld Half Coupling |

| 3000# Forged Socket Weld Coupling | ANSI B16.11 Socket Weld Half Coupling |

| 5 Socket Weld Half Coupling | 1 inch Socket Weld Coupling |

| 8 Socket Weld Coupling | 2 inch Socket Weld Coupling |

| 6000# Socket Weld Coupling | 3 inch Socket Weld Coupling |

| 3/4 Socket Weld Half Coupling | 6 inch Socket Weld Half Coupling |

| 6 Socket Weld Coupling | Socket Weld NPT Coupling |

| 1/2 Socket Weld Coupling | Socket Weld Slip Coupling |

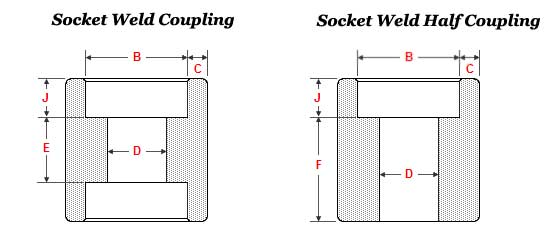

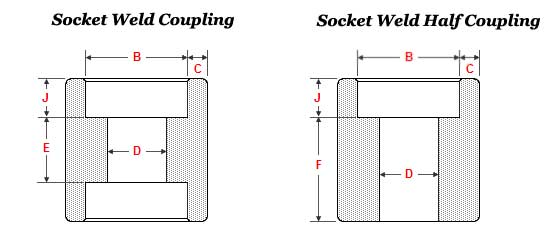

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket wall THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

| NPS | Laying lengths | |||

| Coupling E |

Half coupling F |

|||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

| 2.1/2 | 19 | 42.5 | ||

| 3 | 19 | 44.5 | ||

| 4 | 19 |

47.5 |

||

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket wall THK |

| B | J | D | C | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

| NPS | Laying lengths | |||

| Coupling E |

Half coupling F |

|||

| 1/2 | 9.5 | 22.5 | ||

| 3/4 | 9.5 | 23.5 | ||

| 1 | 13 | 29 | ||

| 1.1/4 | 13 | 30 | ||

| 1.1/2 | 13 | 32 | ||

| 2 | 19 | 41 | ||

ASME B16.11 Socket weld Half Coupling is known to deliver exceptional performance and are generally

developed for meeting the demands. We offer a broad range of Forged Socket weld Half Coupling through a

the worldwide network of stock-keeping branches. This Forged Socket weld Half Coupling is used in various

industries like :

Stainless Steel Forged Socket weld Half Coupling uses in Oil and Gas Pipeline

Forged Socket weld Half Coupling uses in Chemical Industry

Alloy Steel Socket weld Half Coupling uses in Plumbing

Forged Socket weld Half Coupling uses in Heating

Socket weld Forged Half Coupling uses in Water Supply Systems

ANSI B16.11 Forged Socket weld Half Coupling uses in Power Plant

Socket weld Half Coupling uses in Paper & Pulp Industry

Forged Socket weld Half Coupling uses in General Purpose Applications

Forged Socket weld Half Coupling uses in Fabrication Industry

Forged Socket weld Half Coupling uses in Food Processing Industry

Forged Socket weld Half Coupling uses in Structural Pipe

| MIDDLE EAST | AFRICA | NORTH AMERICA | EUROPE | ASIA | SOUTH AMERICA |

| Saudi Arabia | Nigeria | Usa | Russia | India | Argentina |

| Iran | Algeria | Canada | Norway | Singapore | Bolivia |

| Iraq | Angola | Mexico | Germany | Malaysia | Brazil |

| Uae | South Africa | Panama | France | Indonesia | Chile |

| Qatar | Libya | Costa Rica | Italy | Thailand | Venezuela |

| Bahrain | Egypt | Puerto Rica | Uk | Vietnam | Colombia |

| Oman | Sudan | Trinidad And Tobago | Spain | South Korea | Ecuador |

| Kuwait | Equatorial Guinea | Jamaica | Ukraine | Japan | Guyana |

| Turkey | The Republic Of Congo | Bahamas | Netherland | Sri Lanka | Paraguay |

| Yemen | Gabon | Denmark | Belgium | Maldives | Uruguay |

| Syria | Greece | Bangladesh | |||

| Jordan | Czech Republic | Mayanmar | |||

| Cyprus | Portugal | Taiwan | |||

| Hungary | Cambodia | ||||

| Albania | |||||

| Austria | |||||

| Switzerland | |||||

| Slovakia | |||||

| Finland | |||||

| Ireland | |||||

| Croatia | |||||

| Slovenia | |||||

| Malta |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com