+86 151 277 20688

+86 151 277 20688

sales@hgffgroup.com

sales@hgffgroup.com

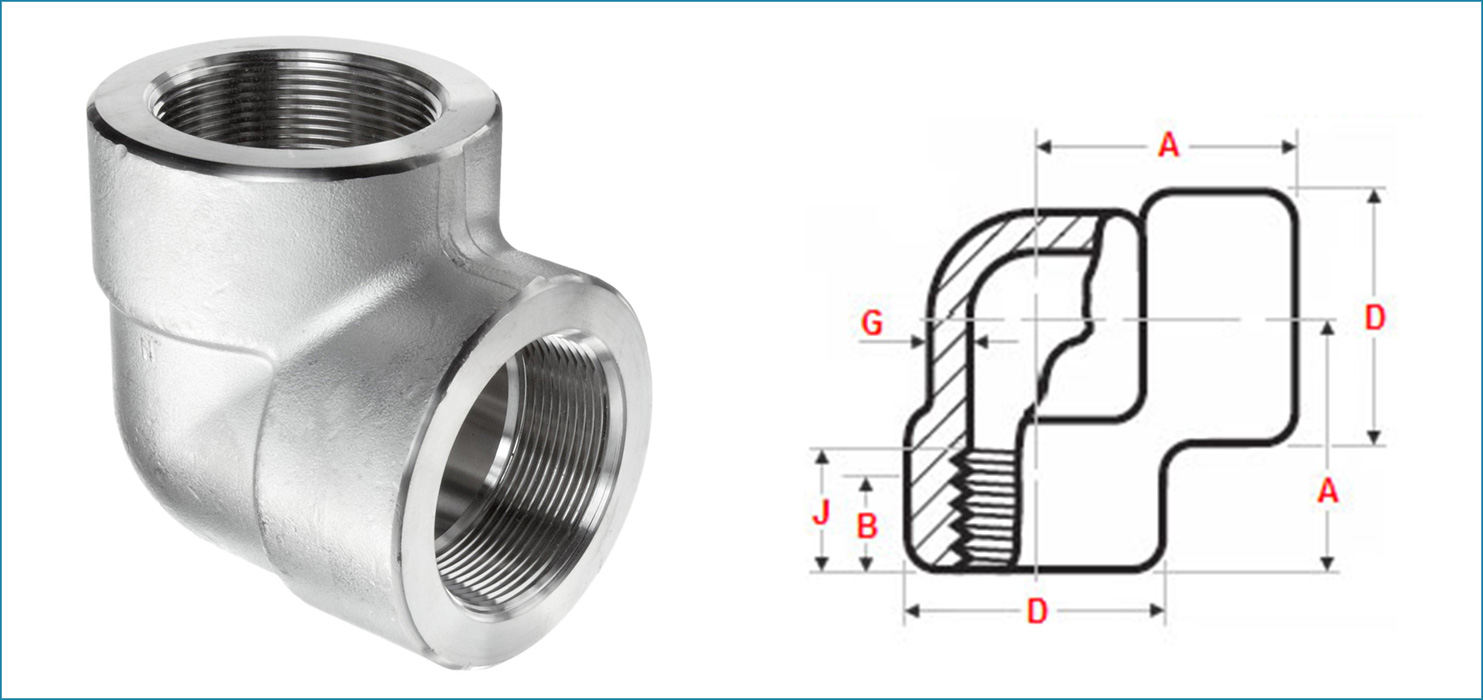

ASME B16.11 Forged Threaded / Screwed 90 Deg Elbow

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B,

API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

1/8″ NB TO 4″ NB

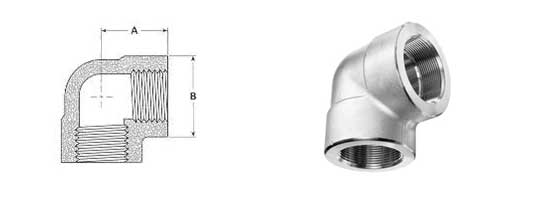

Rising in the national and international markets, HGFF Group Co.,Ltd is maintaining its reputation as a high-end manufacturer, supplier and exporter of Threaded / Screwed 90° Elbows. This fitting makes a 90° change of direction in the run of the pipe. It adds pressure losses to the system due to friction, impact and re-acceleration. The Stainless Steel Threaded 90° Elbow Fittings provides an eternal welded connection for essential applications such as water supply pipelines and other fluid transfer systems. For ANSI B16.11 Forged Screwed 90° Elbows, the ends Threaded 90 Deg Elbow, SS 90 deg. Threaded Elbow, 90 degrees Forged Screwed Elbow can be machined or socketed. These fittings are produced in two types; short radius elbows and long radius elbows. HGFF Group Co., Ltd. is an innovative manufacturer and stockist of ASME B16.11 Threaded / Screwed 90° Elbows. They provide services on the go for the customers and make consistent efforts to keep the clients satisfied

Rising in the national and international markets, HGFF Group Co.,Ltd is maintaining its reputation as a high-end manufacturer, supplier and exporter of Threaded / Screwed 90° Elbows. This fitting makes a 90° change of direction in the run of the pipe. It adds pressure losses to the system due to friction, impact and re-acceleration. The Stainless Steel Threaded 90° Elbow Fittings provides an eternal welded connection for essential applications such as water supply pipelines and other fluid transfer systems. For ANSI B16.11 Forged Screwed 90° Elbows, the ends Threaded 90 Deg Elbow, SS 90 deg. Threaded Elbow, 90 degrees Forged Screwed Elbow can be machined or socketed. These fittings are produced in two types; short radius elbows and long radius elbows. HGFF Group Co., Ltd. is an innovative manufacturer and stockist of ASME B16.11 Threaded / Screwed 90° Elbows. They provide services on the go for the customers and make consistent efforts to keep the clients satisfied

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Form | 90 Deg Threaded Elbow, Threaded Elbow, Threaded Pipe elbow |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Stainless Steel Forged Threaded 90 Deg Elbow :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Forged Threaded 90 Deg Elbow :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Forged Threaded 90 Deg Elbow :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Threaded 90 Deg Elbow :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Forged Threaded 90 Deg Elbow : ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Nickel Alloy Forged Threaded 90 Deg Elbow :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

| Class 2000 | Nominal Pipe Size |

1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| A | – | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0.198 | 0.283 | 0.500 | 0.773 | 1.013 | 1.550 | 2.180 | 3.140 | 6.500 | 10.925 | 26.675 | |

| Class 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.236 | 0.350 | 0.592 | 0.973 | 1.355 | 2.265 | 2.407 | 3.500 | 5.920 | 11.900 | 14.438 | 31.975 | |

| Class 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0.250 | 0.625 | 1.023 | 1.625 | 2.625 | 3.500 | 6.750 | 7.500 | 13.438 | 20.875 | 39.050 | 38.000 | |

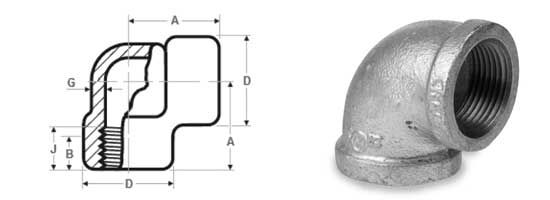

Threaded Elbow Dimensions NPS 1/2 to 4 Class 2000

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | ||

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 33 | 3.18 | 28 | 22 |

| 3/4 | 12.7 | 13.9 | 38 | 3.18 | 33 | 25 |

| 1 | 14.7 | 17.3 | 46 | 3.68 | 38 | 28 |

| 1.1/4 | 17 | 18 | 56 | 3.89 | 44 | 33 |

| 1.1/2 | 17.8 | 18.4 | 62 | 4.01 | 51 | 35 |

| 2 | 19 | 19.2 | 75 | 4.27 | 60 | 43 |

| 2.1/2 | 23.6 | 28.9 | 92 | 5.61 | 76 | 52 |

| 3 | 25.9 | 30.5 | 109 | 5.99 | 86 | 64 |

| 4 | 27.7 | 33 | 146 | 6.55 | 106 | 79 |

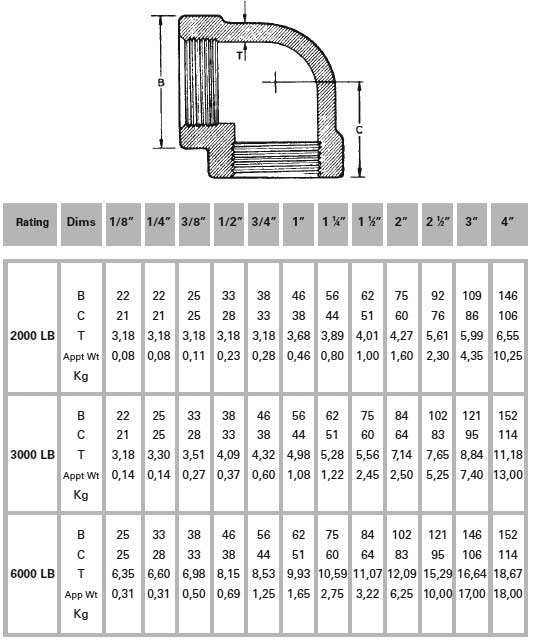

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | ||

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 38 | 4.09 | 33 | 25 |

| 3/4 | 12.7 | 13.9 | 46 | 4.32 | 38 | 28 |

| 1 | 14.7 | 17.3 | 56 | 4.98 | 44 | 33 |

| 1.1/4 | 17 | 18 | 62 | 5.28 | 51 | 35 |

| 1.1/2 | 17.8 | 18.4 | 75 | 5.56 | 60 | 43 |

| 2 | 19 | 19.2 | 84 | 7.14 | 64 | 44 |

| 2.1/2 | 23.6 | 28.9 | 102 | 7.65 | 83 | 52 |

| 3 | 25.9 | 30.5 | 121 | 8.84 | 95 | 64 |

| 4 | 27.7 | 33 | 152 | 11.18 | 114 | 79 |

| NPS | Min Length of Thread |

Outside Dia of Band |

Min WT |

Center to End | ||

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 46 | 8.15 | 38 | 28 |

| 3/4 | 12.7 | 13.9 | 56 | 8.53 | 44 | 33 |

| 1 | 14.7 | 17.3 | 62 | 9.93 | 51 | 35 |

| 1.1/4 | 17 | 18 | 75 | 10.59 | 60 | 43 |

| 1.1/2 | 17.8 | 18.4 | 84 | 11.07 | 64 | 44 |

| 2 | 19 | 19.2 | 102 | 12.09 | 83 | 52 |

| 2.1/2 | 23.6 | 28.9 | 121 | 15.29 | 95 | 64 |

| 3 | 25.9 | 30.5 | 146 | 16.64 | 106 | 79 |

| 4 | 27.7 | 33 | 152 | 18.67 | 114 | 79 |

General notes:

ASME B16.11 90 Degree Threaded / Screwed Elbow are known to deliver exceptional performance and are

generally developed for meeting the demands. We offer a broad range of Forged 90 Degree Threaded Elbow

through a worldwide network of stock-keeping branches. This 90Deg. Threaded Elbow is used in various

industries like :

Stainless Steel 90° Forged Screwed Elbow uses in Oil and Gas Pipeline

90° Forged Threaded Pipe Elbow uses in Chemical Industry

Alloy Steel 90° Screwed Elbow uses in Plumbing

Forged Threaded 90 Degree Pipe Elbow uses in Heating

90 Degree Forged Elbow uses in Water Supply Systems

ANSI B16.11 Forged 90° Screwed Pipe Elbow uses in Power Plant

90° Screwed Elbow uses in Paper & Pulp Industry

90° Degree Threaded Elbow uses in General Purpose Applications

Forged Screwed 90° Long Radius Elbow uses in Fabrication Industry

90° Forged Threaded Elbow uses in Food Processing Industry

Forged Threaded 90° Short Radius Elbow uses in Structural Pipe

| Forged Threaded Elbow 90 Degree | Forged Screwed Long Radius 90 Degree Elbows |

| Threaded Fittings Pipe Elbow | Threaded 90° Short Radius Elbow |

| ASME B16.11 90 deg Threaded Elbow | 90 Degree Elbow 3000LB Threaded |

| Stainless Steel 90 Degree | Screwed Pipe Elbow |

| Suppliers SS 90 Deg. | Forged Screwed Elbows |

| ANSI B16.11 90 Degree Forged Elbow Dealer | BS 3799 Forged 90 Degree Screwed Elbow Exporter |

| Forged Threaded 90 Deg Elbow Stockholder | Threaded 90° Pipe Elbow Distributors |

| Carbon Steel Threaded 90deg.Elbow | High Quality Threaded 90° Elbow Manufacturer |

| ASTM A182 Threaded Stainless Steel 90 Deg Elbows | Duplex Steel 90° Threaded Pipe Elbow |

| Super Duplex Steel 90 Deg Screwed Elbow | Copper Nickel Threaded 90 Deg Elbow |

| High Nickel Alloy 90°Forged Threaded Elbow | Hastelloy Threaded 90° Pipe Elbow Stockist |

| Titanium 90 Degree Screwed Elbow | Inconel Threaded 90 Deg Pipe Elbow |

Phone+86 151 277 20688

Phone+86 151 277 20688 Tel+86 151 277 20688

Tel+86 151 277 20688 E-mailsales@hgffgroup.com

E-mailsales@hgffgroup.com